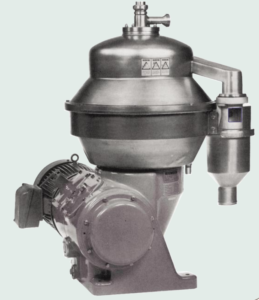

Alfa Laval AFPX 610 Separator

High g-forces, high demands on clarification capacity and outstanding reliability –These are the main criteria that have formed the basis for the design of the new AFPX 610 centrifuge.

Product Description

Applications

The AFPX 610 is a solids ejecting disc stack centrifuge designed for intermittently discharge of solids, while splitting a tight emulsion of two liquids. It is mainly usedin the animal and fish processing industry, where it is used for a number of different separation and purification duties, such as:

– Meat and fish extract

– Gelatine clarification

– Fats and oils purification

Special Features

The AFPX is designed to separate at very high g-force to improve purification and clarification of any feed. The device that accelerates the feed up to the speed of the rotor, is specially designed to do so in a gentle manner, which further helps to increase the separation performance. The outlet of the AFPX 610 is designed to give the oil phase a final polish. When the oil phase is sprayed out into the collecting frame, the last traces of water is separated from the oil phase by evaporation.

Standard design

The bowl is mounted on a vertical spindle that is driven via a clutch and a worm gear. The bottom part of the machine forms a housing for the worm gear, where also the oil bath is contained.

The upper part of the machine, the frame, carries the inlet device and is equipped with connections to transport the separated liquids away from the machine.

All liquid wetted parts are made in high-grade stainless steel. The design conforms with a number of EC directives and the machine is made in accordance with the general directives for machinery. The machine is available in purifier or concentrator execution.

Standard equipment

Separator with feed and discharge devices, vibration dampers, earth connecting kit, vibration switch, temperature sensor for motor winding, speed sensor, cover interlocking kit, standard set of spare parts, set of tools, revolution counter, set of erosion protecting parts and flange motor.

Auxiliary equipment

Process components including in- and outlet pipes, valves and flexible connections. Programmable logic control unit. Starter for electric motor.