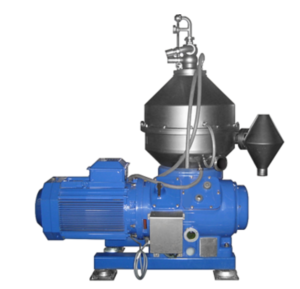

BRUX 510

Alfa Laval BRUX, a VLB-validated separator, is specifically designed for continuous in-line removal of surplus yeast as well as micro-organisms and cell debris. The gentle treatment afforded by the low shear forces in the centrifuge maintains high yeast vitality and high quality in the recovered beer, reducing costs. Unique design features ensure highly efficient separation in an automated process operating under strict hygienic standards.

Product Description

Alfa Laval BRUX, a VLB-validated separator, is specifically designed for continuous in-line removal of surplus yeast as well as micro-organisms and cell debris. The gentle treatment afforded by the low shear forces in the centrifuge maintains high yeast vitality and high quality in the recovered beer, reducing costs. Unique design features ensure highly efficient separation in an automated process operating under strict hygienic standards.

Traditional separators only discharge the separated yeast intermittently by opening the bowl for short intervals. By contrast, in the well proven Alfa Laval system, the yeast leaves the separator in a continuous flow, which means that a much smaller separator is sufficient.

Less space, greater capacity

The Alfa Laval process module therefore takes up much less space than a traditional separator. Nevertheless, it can process greater volumes (20–60 hl/h) of beer-saturated yeast, with substantially better beer recovery as well as improved concentration of the yeast (20% dry matter content and more).

The BRUX 510 is equipped with Oxy-Stop, the hydro-hermetic seal for minimum oxygen pick-up of the clarified beer.

How it works

The yeast is forced to the periphery of the BRUX 510 separator. From there, it is pushed through special concentrate tubes towards the centre to vortex nozzles, from which it leaves the separator under pressure, via a built-in paring tube. Special vortex nozzles automatically regulate the flow of the concentrate. Thus yeast is treated very gently.

The beer is clarified on the disc stack and leaves the separator under pressure through paring disc and Oxy-Stop.

Dilution ensures consistency

Because of the way this nozzle separator works, it is important that the flow intended for separation has a relatively stable consistency. To ensure this, a beer standardization unit is installed upstream to dilute the incoming yeast/ beer mixture to approx. 25–45% by volume, using deaerated water.

Dilution ensures high yield

An important effect of higher dilution is a greater recovery yield, because more of the beer gets washed out of the yeast slurry.

Recovery yield and thus extract recovery can be further increased by letting diluted concentrated yeast from the first pass to pass the BRUX 510 recovery module for the second time BRUX recovery module twice.