Alfa Laval CPM Constant-Pressure Modulating Valve

CPMI-2, CPMI-D60 and CPMO-2 are sanitary constant-pressure valves. CPMI-2 and CPMI-D60 (Constant-Pressure Modulating Inlet) maintain a constant pressure in the process line at the inlet side of the valve. Typical applications are after separators, heat exchangers or overflow valves. CPMO-2 (Constant-Pressure Modulating Outlet) maintains a constant pressure in the process line at the outlet side of the valve. Typical applications are before filling/bottling machines etc.

Product Description

Working principle

The valves are remote-controlled by means of compressed air. A diaphragm/valve plug system reacts immediately to any alteration of the product pressure and changes position so that the present pressure is maintained.

Standard design

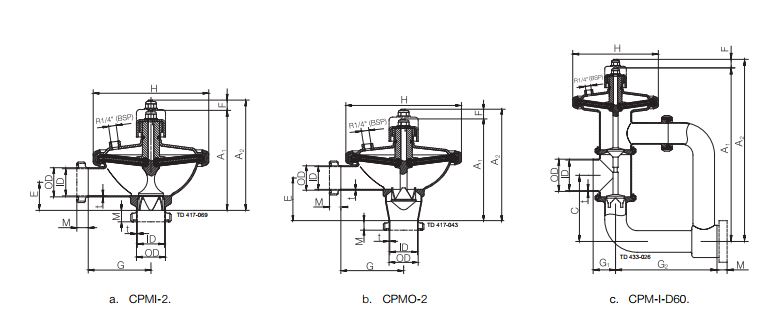

The CPMI-2 and CPMO-2 consist of a valve body with valve seat, cover, a valve plug with a diaphragm unit and a clamp. The cover and the valve body are clamped together. The valve body and the seat are welded together. The CPM-I-D60 consists of upper and lower valve bodies, an inlet tube, a cover, a valve plug with diaphragm unit and clamps. The cover and the valve bodies are clamped together.

Technical Data

Max. product pressure: . . . . . . . . . . 1000 kPa (10 bar).

Max. product pressure . . . . . . . . . . 145 PSI

Min. product pressure: . . . . . . . . . . 0 kPa (0 bar).

Min. product pressure . . . . . . . . . . . 0 PSI

Temperature range: . . . . . . . . . . . . . 10°C to 95°C (EPDM).

Temperature range: . . . . . . . . . . . . . 14° F to 203° F

Temperature range with upper diaphragm

in PTFE/EPDM: . . . . . . . . . . . . . . . 10° C to +140° C. (Higher on request).

Temperature range with upper diaphragm in PTFE/EPDM . . . . . . . . . . . . . . . . 14° F to 286° F (Higher on request)

Air pressure (CPMI-2/CPMO-2): . . . . . 0 to 800 kPa (0 to 8 bar).

Air pressure (CPMI-2/CMPO-2) . . . . . 0 to 116 PSI

Air pressure (CPM-I-D60): . . . . . . . . 0 to 600 kPa (0 to 6 bar).

Flow Kv 23, fully open (Dp = 1 bar): . . Approx 23 m3/h.

Flow Kv 23, fully open (Dp = 14.5 psi): Approx 812 gpm

Flow Kv 7 (∆p = 1 bar): . . . . . . . . . . Approx 7 m3/h.

Flow Kv 7 (∆p = 14.5 psi): . . . . . . . . Approx 247 gpm

Flow Kv 9 (∆p = 1 bar): . . . . . . . . . . Approx 9 m3/h.

Flow Kv 9 (∆p = 14.5 psi): . . . . . . . . Approx 317.8 gpm.

Flow Kv2/15, low capacity (∆p = 1 bar): Approx 2 m3/h.

Flow Kv2/15, low capacity (∆p = 14.5 psi): . . . . . . . . . . . . . . . . . . . . . . . Approx 70.6 gpm

(Alternative size) . . . . . . . . . . . . . . . (regulating area). Approx. 15m3/h. (CIP area).

(Alternative size) . . . . . . . . . . . . . . . (regulating area). Approx. 529.7 gpm. (CIP area).

Flow range Kv60, fully open (∆p = 1 bar)

(CPM-I-D60) . . . . . . . . . . . . . . . . . Approx 60 m3/h.

CPMI-2 and CPMO-2 are authorized to carry the 3A Symbol

Physical Data

Materials

Product wetted steel parts: . . . . . . . . 1.4404 (316L).

Product wetted steel parts: . . . . . . . . Acid-resistant steel AISI 316 L

Other steel parts: . . . . . . . . . . . . . . 1.4301(304).

Other steel parts: . . . . . . . . . . . . . . Stainless steel AISI 304

Lower diaphragm: . . . . . . . . . . . . . . PTFE covered EPDM rubber

Upper diaphragm . . . . . . . . . . . . . . NBR

Finish . . . . . . . . . . . . . . . . . . . . . . 32 RA

Air Connections: R 1/4″ (BSP), internal thread.

Options

A. Male parts or clamp liners in accordance with required standard.

B. Pressure gauge 0-87 PSI, 1.5-inch Pressure gauge 0-145 PSI, 1.5-inch

C. Air pressure regulating valve kit, 0-8 bar.

D. Air pressure regulating valve kit, 0-116 PSI (D).

E. Air throttling valve for adjustment of regulating speed for the CPM-2 valve.

F. Booster for product pressure exceeding the available air pressure. (Product pressure = 1.8 x air pressure).

G. US 3A version available on request for CPM-2 valves only

H. 3A (Sanitary Standard) labelling on request for CPM-2 Valves.

Material grades CPM-2

I. Upper diaphragm of PTFE covered EPDM and O-ring of FPM covered EPDM, (for temperature 95-140°C).

J. Upper diaphragm of PTFE covered EPDM and O-ring of Fluorinated rubber (FPM) covered EPDM rubber, (for temperature 203 – 284°F).

K. Both diaphragms of solid PTFE and O-ring of FPM (for temperatures above 140°C).

L. Both diaphragms of solid PTFE and O-ring of Fluorinated rubber

(FPM) (for temperatures above 284°F)

Material grades CPM-I-D60

M. Upper diaphragm of PTFE covered EPDM.

N. Valve body seal rings of NBR or FPM.

O. Guide O-ring of FPM (for temperatures above 95°C)

Fig. 1. Principle

CPMI-2 CPMO-2

a. Reduced product pressure.

CPMI-2 CPMO-2

b. Increased product pressure.

CPMI-2 and CPM-I-D60 opens at increasing product pressure and vice versa.

CPMO-2 closes at increasing product pressure and vice versa.

Diaphragm Unit

CPMI-2 and CPMO-2: The diaphragm unit consists of a stainless steel disc which is divided into sectors and of flexible diaphragms which are placed on each side of the sectors. CPM-I-D60: The diaphragm unit consists of two flexible diaphragms supported by 12 stainless steel sectors in between them.

Note! For further details, see also instructions ESE01825 and ESE01834

Fig. 2. CPMI-2 with pressure regulating valve and pressure gauge

The valves operate without a transmitter in the product line and require only a pressure regulating valve for the compressed air and a pressure gauge in the product line.

Pressure drop/capacity diagrams

Note!

Note!

For all diagrams the following applies:

Medium: Water (20°C).

Measurement: In accordance with VDI 2173.

Alfa Laval recommend max. flow velocity in tubing and valves to be 5m/sec.

Example 1:

Pressure drop ∆p = 200 kPa.

Flow Q = 8 m3/h.

Select: CPM-2, Kv 23 which at working point will be 48% open.

Example 2:

CPMI-2:

Pressure drop ∆p = 300 kPa.

Flow Q = 1 m3/h.

Select: CPMI-2, Kv 2/15 which at working point will be approx. 35% open equal to about 50% of the regulating area.

NOTE! For all diagrams the following applies:

Medium: Water (68° F)

Measurement: In accordance with DI 2173

Alfa Laval recommend max. flow velocity in tubing and valves to be 5 m/sec.

Example of using the diagram:

1. Pressure drop ∆p = 300 kPa.

2. Flow = 50m3/h.

The intersection is on the 50% curve.

Note! Always try to get as close as possible to the 50% open curve. If the CPM-I-D60 is too big select from the CPMI-2 curves.

Example 1:

Pressure drop ∆p = 29 PSI

Flow Q = 35.2 GPM

Select: CPM-2, Cv 27 which at working point will be 48% open.

Example 2:

CPMI-2:

Pressure drop ∆p = 43.5 PSI

Flow Q = 4.4 GPM

Select: CPMI-2, Cv 2/18 which at working point will be approx. 35% open equal to about 50% of the regulating area.

Example of using the diagram:

1. Pressure drop ∆p = 36 PSI

2. Flow =220 GPM

The intersection is on the 50% curve.

Note! Always try to get as near as possible to the 50% open curve.

Dimensions (mm)

Dimensions (in.)