Alfa Laval SMP-BC Mixproof Valve

SMP-BC is a hygienic pneumatic seat valve, designed for safety and leak detection when two different products flow through only one valve. The valve is often used as a part in CIP return lines or other systems not experiencing pressure spikes offering leakage detection for greater safety.

Product Description

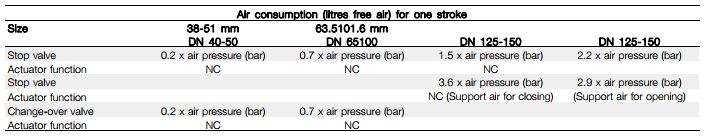

Working principle

SMP-BC is remote-controlled by means of compressed air. The valve is a normally closed (NC) valve. The valve is fitted with two small pneumatic normally open (NO) valves, a detecting valve and a CIP-valve. The valve plug (the upper plug in a change-over valve) has two seals, forming a leakage chamber under atmospheric pressure between them. Leaking product flows into the leakage chamber and is discharged through the detecting valve. SMP-BC can be cleaned by CIP by supplying compressed air to the actuator (see fig. 1). During cleaning of the valve, flow pattern against the closing direction of the valve plug makes SMP-BC insensitive to water hammer.

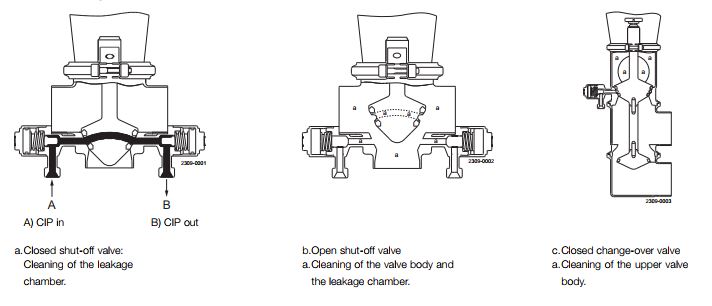

Technical Data

Max. product pressure (depending on

valve specifications): . . . . . . . . . . . . 1000 kPa (10 bar).

Min. product pressure: . . . . . . . . . . Full vacuum.

Temperature range: . . . . . . . . . . . . . -10°C to +140°C (EPDM).

Air pressure: . . . . . . . . . . . . . . . . . 500 to 800 kPa (5 to 8 bar).

Physical Data

Product wetted steel parts: . . . . . . . . . . . . 1.4401 (316L).

External surface finish . Semi-bright (blasted)

Internal surface finish . . Bright (polished), Ra < 1.6 µm

Other steel parts: . . . . 1.4301 (304).

Product wetted seals: . EPDM.

Other seals: . . . . . . . . NBR

.

Valve body combination

Type 20 and 30 body versions are on request available in following configurations:

– Tee welded on lower port in 0 or 90 deg. version

– Bend welded on lower port in 0, 90, 180 or 270 deg. version

The three body version is on request available in following configurations:

– Type 121, 122, 211, 212, 221 & 222

Standard design

SMP-BC is available in two versions, as a shut-off valve with one valve body or as a change-over valve with three valve bodies (sizes DN125-150 only as shut-off valve). The valve bodies and the external actuator are clamped together. SMP-BC is fitted with one detecting valve and one CIP-valve. The seals and the lip seal can be serviced after removing the actuator. It is recommended, due to the valve size and weight, to use supporting equipment, handling and installing the valve. Guidelines are given in the instruction manual (IM70771). Alfa Laval is not able to supply the recommended supporting equipment.

Options

A. Male parts or clamp liners in accordance with required standard.

B. Control and Indication: IndiTop, ThinkTop or ThinkTop Basic.

C. Actuator with stronger spring.

D. Larger actuator for valve sizes 38-51 mm/DN40-50.

E. CIP installation kits.

F. Other valve body combinations.

G. Surface roughness, product wetted parts: Ra ≤0.8 μm.

H. Product wetted seals of NBR or FPM.

I. Service tools for actuator.

J. Tool for plug seals (Necessary for changing the seals).

Note!

For further details, see also instruction IM 70771.

Operation/cleaning

Pressure drop/capacity diagrams

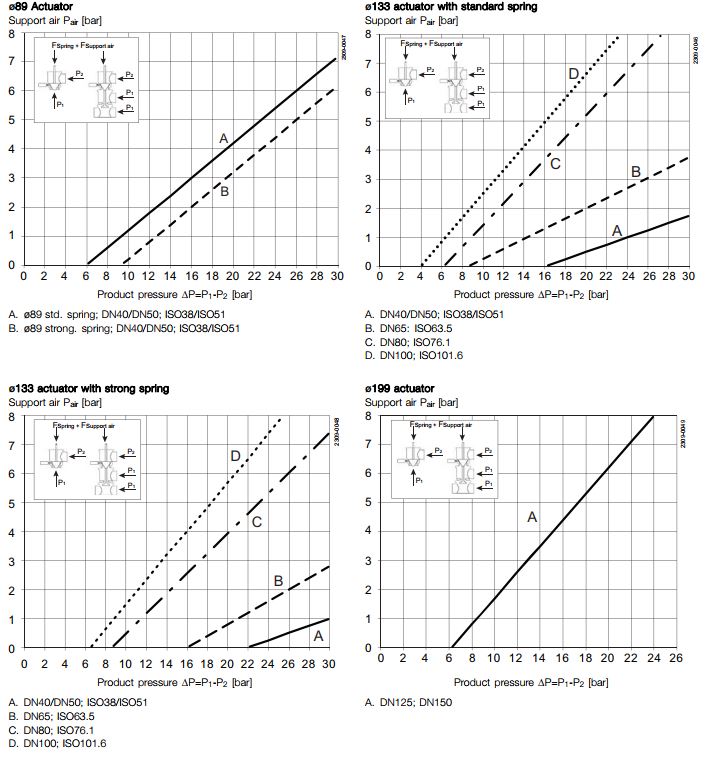

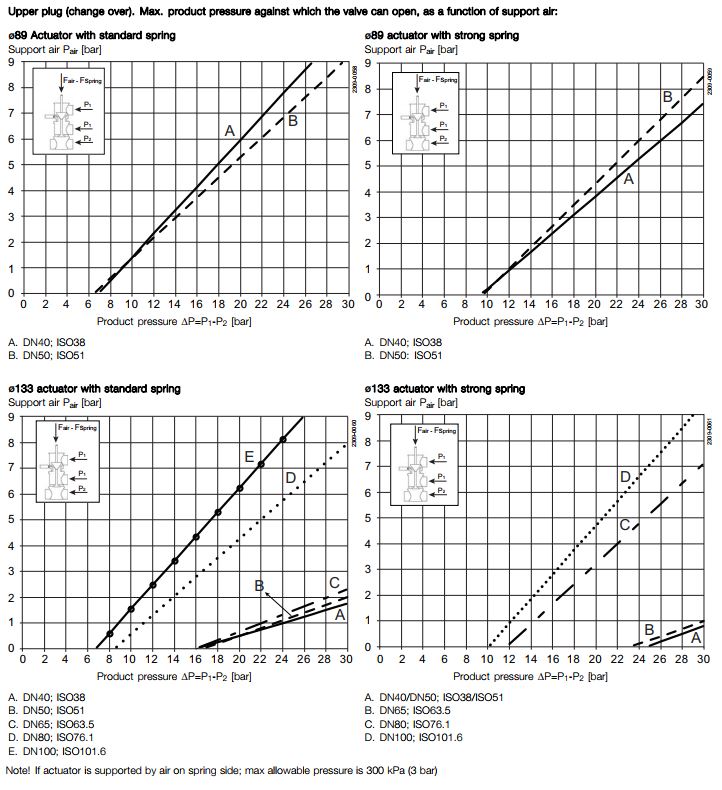

Max pressure difference/support air pressure diagrams

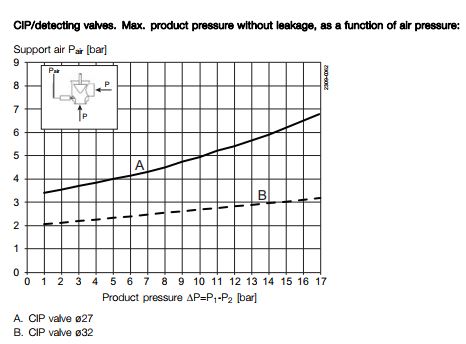

Upper plug max. product pressure without leakage, as a function of support air:

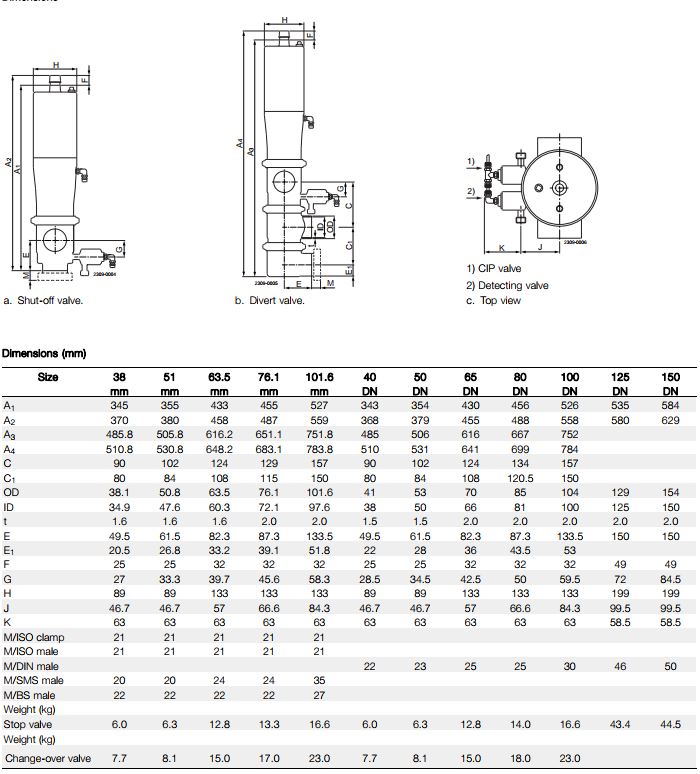

Dimensions

Dimensions

Air Connections Compressed air:

R 1/8″ (BSP), internal thread.

CIP connection:

R 3/8″ (BSP), external thread.

Leakage connection:

R 3/8″ (BSP), external thread.

Caution, opening/closing time:

Opening/closing time will be affected by the following:

– The air supply (air pressure).

– The length and dimensions of the air hoses.

– Number of valves connected to the same air hose.

– Use of single solenoid valve for serial connected air actuator functions.

– Product pressure.