Alfa Laval Unique DV-ST UltraPure

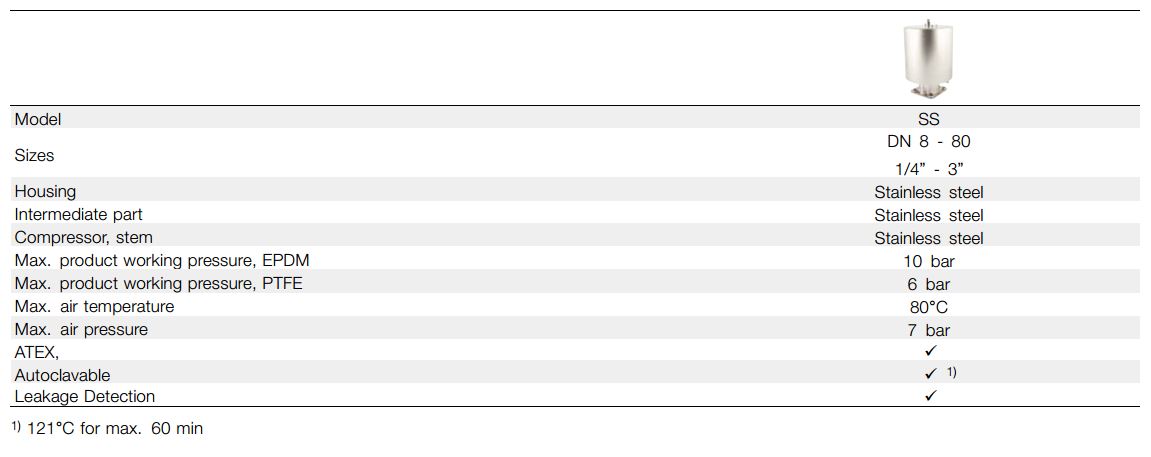

The standard Unique DV-ST UltraPure is designed either for manual operation or for Pneumatic operation. The valve consist of a valve body, diaphragm, handle or actuator. Optional Sensing and control units are available. With a fully modular design the Unique DV-ST UltraPure can be built to meet virtually any demand within most industries. The valves are primarily used in biotech and pharmaceutical industries however they are also widely used in aseptic and hygienic processes as well as in utility systems within dairy, beverage and food industries.

Product Description

Working principle

Manual operation

A simple turn of the handle will push the compressor downwards on the diaphragm, pressing the diaphragm against the weir of the valve body thereby closing the valve.

Pneumatic operation

The actuator controls the axial movement of a piston, thereby opening or closing the valve depending on the actuator function.

Valve Body Design

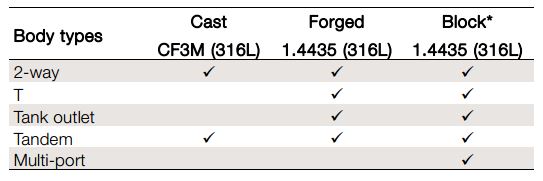

The valve bodies are available in a wide variety of valve types and configuration options (dimension standards, connections, surface finish and material).

- 2-way

- T

- Tank outlet

- Tandem

- Multi-port

Configurator available.

Physical data

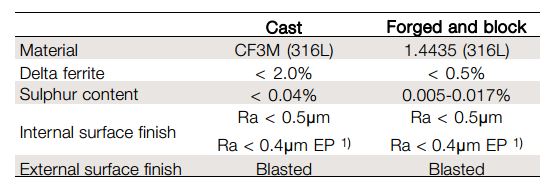

Materials

* Other materials on request

1)Electro Polished 0.5µm = SF1, 0.4µm = SF4

Sensing and control units:

A wide range of sensing and control units are available for actuators consisting of:

- Controls unit

- Indication units

- ATEX units

- Stroke limiters

Documentation

All UltraPure valves are delivered with our comprehensive Q-Doc documentation package, which includes:

- 3.1/ MTR traceability certificate corresponding to EN 10204

- FDA – Declaration of conformity to FDA (CFR 21: 177.2600 or 177.1550)

- USP – Certificate of conformity to USP Class VI (Chapter 88, biological reactivity test)

- TSE/ADI – Declaration. (Transmissible Spongiform Encephalopathy/Animal Derived Ingredients)

- Surface finish conformity declaration. The following documentation is available upon request:

- Surface finish certificate (Ra test results)

- ATEX certificate

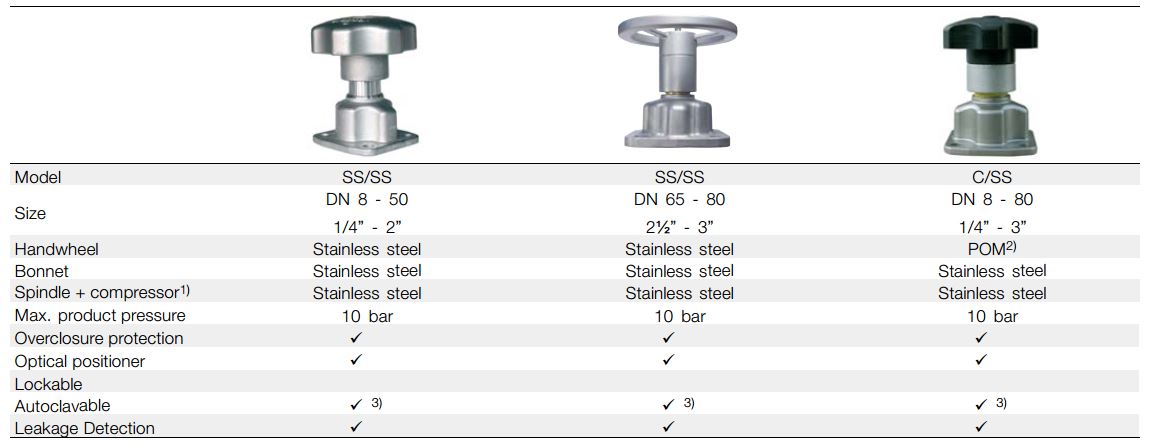

Handle and actuator:

The diaphragm valves can be operated by a handle or a pneumatic actuator. Alfa Laval offers 2 different types of manual handles and 1 type of pneumatic actuator

Actuator

Handles

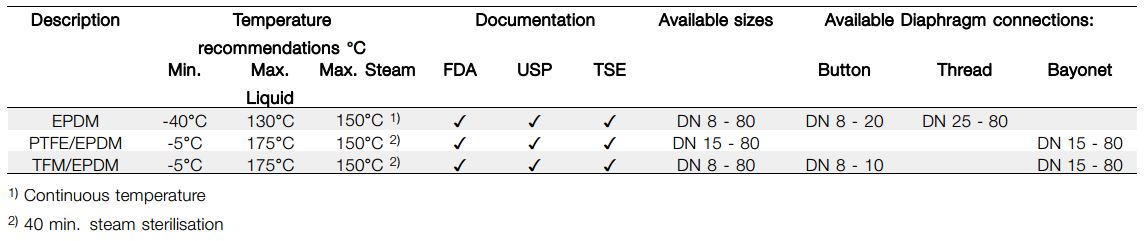

Diaphragms

The diaphragms are available as soft elastomer (EPDM) as well as hard elastomers (PTFE/EPDM and TFM/EPDM). The hard elastomers are supported by a soft elastomer (EPDM). The 2-piece design allows the two elastomers to work independently of each other, thereby reducing tension caused by different thermal properties.

Diaphragms are available with 3 different types of connections: thread, bayonet and button connection.

- Threaded connections are used on soft elastomers ≥ DN 25 (1″)

- Bayonet connections are used on all hard elastomer ≥ DN 15 (1/2″)

- Button connections are used on all small sizes.

Material selection:

Each application has different working conditions and therefore different demands on the diaphragm. In order to select the most suitable diaphragm for your application, the following factors should be considered:

- Working pressure

- Application temperatures

- Process fluids (product, cleaning liquid, sterilisation, passivation, etc.)

Soft elastomer (EPDM) is suitable for most applications and for high working temperatures. Including continuous steam application. Hard elastomers offer the highest possible degree of chemical resistance. Our TFM (PFTE grade) elastomer is a more flexible material and has some of the features of soft elastomer including for example low creep.

Diaphragm properties:

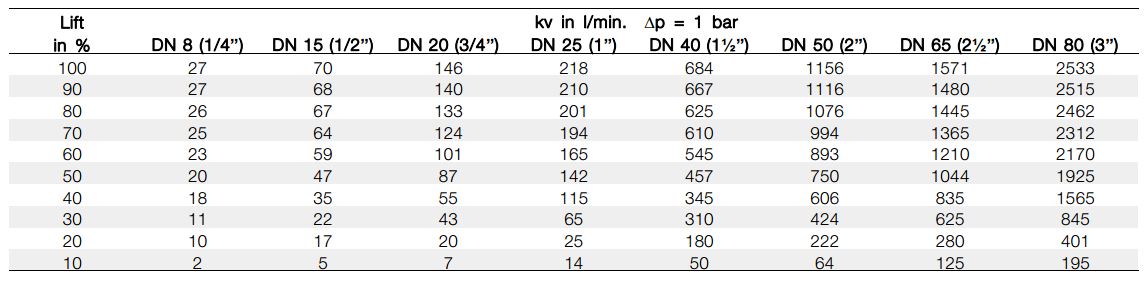

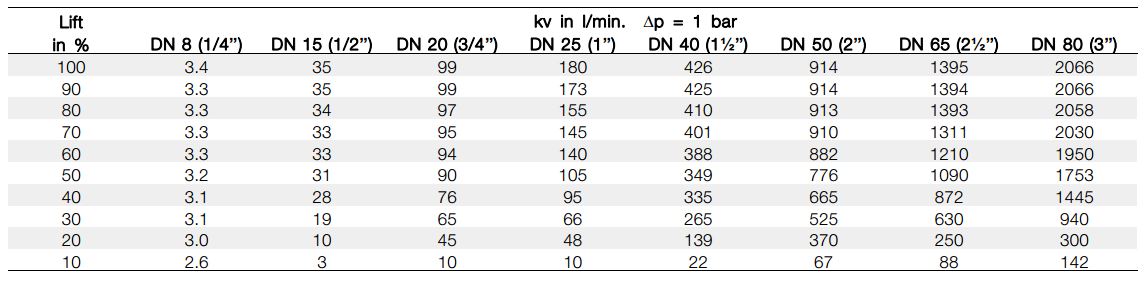

Pressure drop / capacity table

Kv value (Pipe standard ISO 4200)

Kv value (Pipe standard O.D. Tubing)

Cv = 1.16 x Kv

Note! For the diagrams the following applies:

Medium: Water (20 °C)

Measurement: In accordance with VDI2173

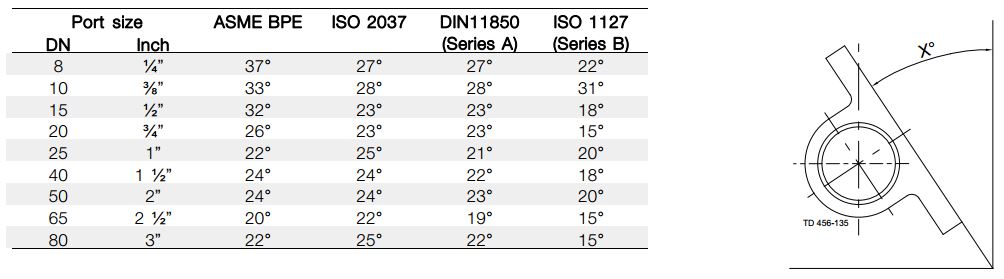

Drain angle x :