Alfa Laval Unique Mixproof Large Particle Valve (Unique LP-F)

This Unique Mixproof LP-F valve is based on the well proven and exceptionally flexible design of the Unique Mixproof valves. The valves are designed for gentle handling of the product containing large particulates up to 1¾” (45 mm) or products with high viscosity. Additional to the Unique Mixproof Large Particle valve (LP) the LP-F is equipped with a lower flush to enable 100% cleanability of the lip seal in the lower sealing element through seat-lift cleaning alone. This an improved performance compared to Spiral clean on the lower plug and reduces the need for additional utility installations for external CIP.

Product Description

Working principle

Unique Mixproof LP-F is remote-controlled by means of compressed air. The valve is a normally closed (NC) valve. It is as standard supplied seat lift, which enables handling of two different products at the same time, or safe handling of one product while seat-lift cleaning operations are being conducted in the other portion of the valve – all without any risk of cross-contamination. The 6” valve is as standard also equipped with balanced lower plug to protect against the effects of high pressure and water hammer. The 4” valve is, in order to accommodate 1½” (45mm) particles, not supplied with balanced lower plug. The 4” is however as standard equipped with a boost actuator to accommodate a product pressure of up to 10 bar. When seat lift of the lower plug is performed the valve will simultaneously clean the lower plug seal as well as the lover sealing element lip seal.

Technical Data

Max. product pressure: .1000 kPa (10 bar)

Min. product pressure: .Full vacuum.

Temperature range: . . . .-5°C to +125 °C (Depending on elastomer type)

Air pressure: . . . . . . . .Max. 8 bar

Materials

Product wetted steel parts: . . . . . . . . . . . . 1.4404 (316L)

Other steel parts: . . . . 1.4301 (304)

External surface finish . Semi-bright (blasted)

Internal surface finish . . Bright (polished), Ra < 1.6µm

Product wetted parts: . EPDM

Other seals:

CIP seals: . . . . . . . . . EPDM

Actuator seals: . . . . . . NBR

Guide strips . . . . . . . . PTFE

Availability

This LP-F edition of the Unique Mixproof valve is a high-end valve with regards to process security as well as from a sanitary point of view. The Unique Mixproof LP-F valve is available in 4″ and 6″ sizes.

Options

– Male parts or clamp liners in accordance with required standard.

– Control and Indication: ThinkTop or ThinkTop Basic.

– Side indication for detection of upper seat lift

– Product wetted seals in HNBR, NBR or FPM

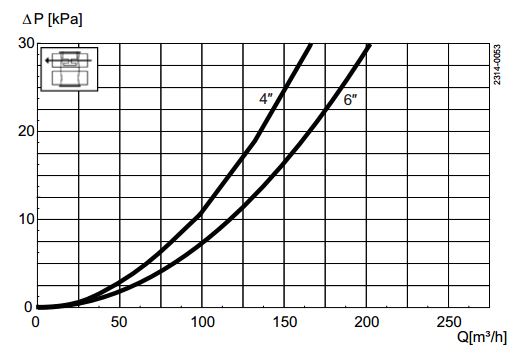

Pressure drop/capacity diagrams

Fig. 2. Pressure drop/capacity diagram, upper bodies.

Fig. 3. Pressure drop/capacity diagram, between bodies.

Fig. 4. Pressure drop/capacity diagram, lower body.

Note! For the diagrams the following applies:

Medium: Water (20°C).

Measurement: In accordance with VDI 2173

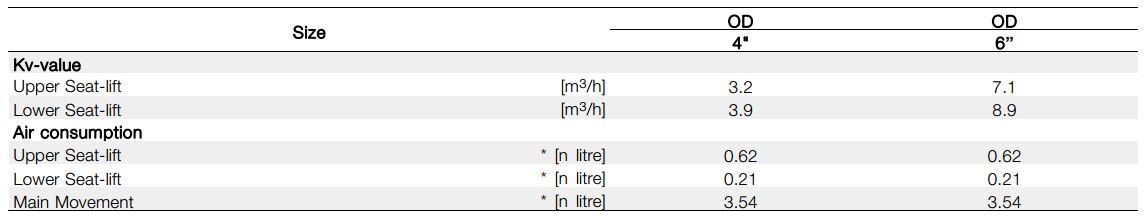

Air and CIP consumption

Note

* [n litre] = volume at atmospheric pressure

Formula to estimate CIP flow during seat lift:

(for liquids with comparable viscosity and density to water):

Q = Kv ·√∆ p

Q = CIP – flow (m3/h).

Kv = Kv value from the above table.

∆ p = CIP pressure (bar).

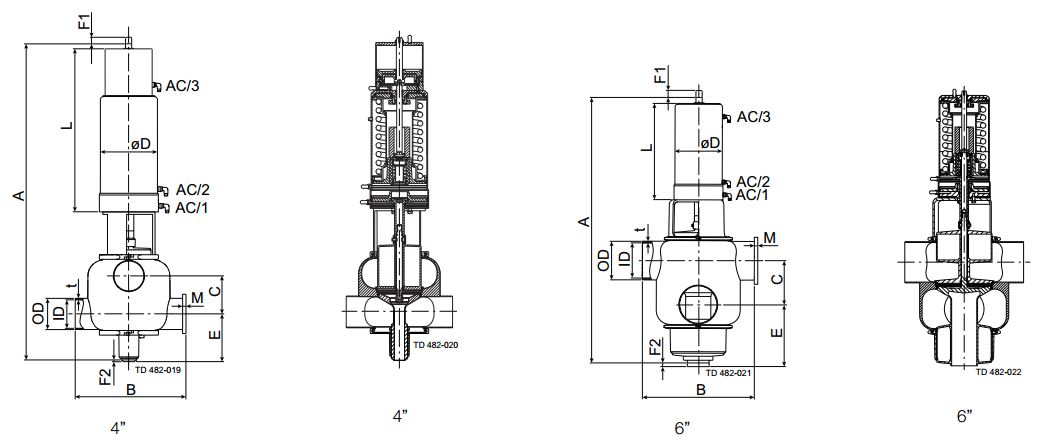

Dimensions

NOTE!

**The measure C can always be calculated by the formula

C =½ID-upper + ½ID-lower + 26mm