Fristam FK positive displacement pumps

These models are distinguished by extremely narrow clearance in the pump chamber and an all-encompassing gland sealing. They are designed for outstanding suction performance and high flow rates with highly viscous products. Pumps from the FK series are suitable for high-differential heads. They can be used in a wide variety of situations from food and beverage to pharmaceutical and chemical applications.

Product Description

Hygienic Standards

Fristam FK pumps meet the world’s strictest standards. Their superior quality is reflected in the use of corrosion resistant materials such as chromium molybdenum steel 316L with a minimum thickness of 6.0mm. In addition 3.1 material certification (certificate available upon request) and FDA certified elastomers guarantee maximum safety in the process.

Self-Priming Operation

The FK series’ extremely tight internal clearances facilitate vacuum operation. Atmospheric or system pressure transfers the product into the pump chambers without rubbing or damage. The suction performance is excellent throughout the entire operational range up to 20 bar, making the FK ideal for products with high viscosities up to 1,000,000 mPas.

Great Reliability

As a result of their sturdy and compact design in combination with Fristam’s superior manufacturing FK pumps have proven to operate with very low downtimes and exceptional durability. Their smart layout enables wear parts to be exchanged quickly and with only minor effort, making any pump from the FK series a highly profitable investment.

Gentle Product Handling

The FK pistons’ special shape guarantees almost perfect displacement. This results in an exceptionally smooth product flow with only minimal shearing and astoundingly gentle transportation, even of delicate non-homogenous or sensitive goods at various speeds.

Constant Efficiency

The flow rate can be adjusted to operating conditions independent from system pressure, simply by changing the pump speed. The change of flow does not influence the pump’s efficiency. Of course, all FKs are designed for CIP and SIP.

Precise Metering

FK pumps are ideal for filling applications wherever precise quantity is required, making them suitable for demanding processes for example in pharmaceuticals, dairy or chemical industries.

Circumferential Pistons

With a choice of two rotor types any pump from the FK series can be perfectly matched to your application. We offer one- and two-wing rotors for all five FK pump sizes. The rotating pistons are a perfect example of Fristam’s high-precision engineering. They are perfectly matched to the FK’s pump body. This created a long sealing path. Without having to use valves or other complex parts the result is a smooth product flow, free of slippage, destructive pulse, pressure peaks or backflow loss.

One-Wing Rotor

This lobe is specifically designed for supremely gentle handling of in-homogeneous products with large-volume additions such as fruit salad, strawberry preserve, potato salad, canned fruit, berry compote, etc…

Two-wing rotor

The double-winged lobe is standard for the FK series. It is recommended for high-revolution processes. Its extremely low shear makes it ideal for products such as thick sauces, cheese spread, soup and chocolate.

The double-winged lobe is standard for the FK series. It is recommended for high-revolution processes. Its extremely low shear makes it ideal for products such as thick sauces, cheese spread, soup and chocolate.

Construction Specifics

Fristam’s FK series is characterized by extremely tight clearances in the pump interior. Together with the special seal area, the FK’s short and sturdy shaft contributes to absolutely minimal distortion during process. The FK’s excentric design principle in the mechanical seal provides functional protection against twisting and leakage. The overall results are absolute reliability and remarkably gentle operation.

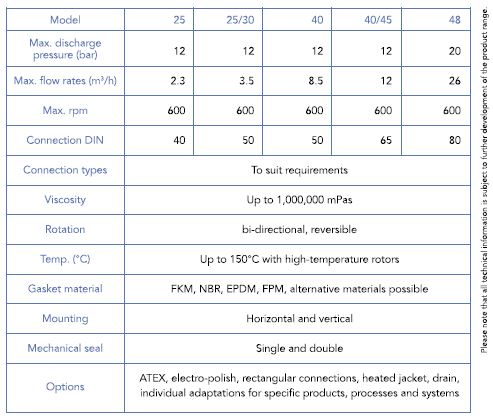

Fristam FK Series Technical Specifications

Characteristic Curves*