INOXPA Tank Bottom Seat Valve NLF

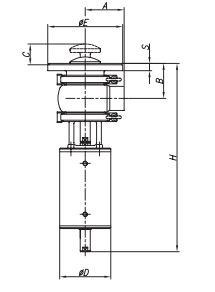

The NLF valve is a pneumatically actuated single seat valve designed for assembly at the bottom of the tanks in the dairy, food-processing industries, beverage production, pharmaceutical and fine chemicals industries.

Product Description

Application

Operating principle

The seat valves are actuated by a single- or double-acting actuator. The shaft is actuated by the supplied compressed air and opens or closes the valve. Possible configuration of the valve: the valve seat opens into the valve to avoid accidental openings in case of overpressure in the line and to avoid possible contact with the product recovery scrapers.

Design and features

- Total drainage prevents the stagnation of the product.

- Normally closed valve (closed by spring) – standard version.

- Normally open valve (opened by spring) by a simple turn of the pneumatic actuator.

- The valve seat opens into the tank to avoid accidental openings in case of excessive pressure in the tank.

- 360º adjustable body, even after welding the flange to the tank.

- Open lantern for visual inspection of the shaft sealing.

- Easy disassembly by loosening the clamp.

- Connections: weld (mm or inches).

Materials

Parts in contact with the product AISI 316L

Other stainless steel parts AISI 304

Gaskets EPDM according to FDA 177.2600

Internal surface finish Ra ≤ 0,8 μm

External surface finish Bright polish

Options

- Manual actuation.

- Steam barrier (if shaft sterilisation is required).

- C-TOP control unit.

- Jacketed body.

- Larger actuator sizes.

- Internal surface finish: Ra ≤ 0,5 μm.

- Gaskets: NBR or FPM.

- Connections: DIN, Clamp, SMS, RJT, FIL-IDF, etc.

- Double-acting actuator.

- “Twin-Stop” actuator.

- External position sensors.

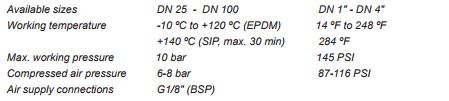

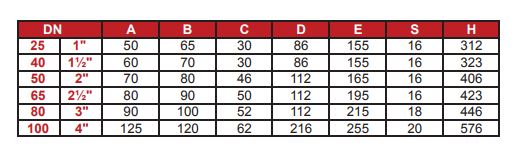

Technical specifications