Pentair Powder Butterfly Valves F250P/F251P Ski-Jump

Pentair Powder Butterfly Valves F250P/F251P Ski-Jump are used in powder conveying/transport applications. Our comprehensive valve line features both manual and pneumatic drive options, including lockable handles and vertical actuators.

Offering a comprehensive range of butterfly valves for a wide range of applications on powder conveying systems for the food, dairy, pharmaceutical, and beverage industries. The F250P/F251P Ski-Jump Valve features advanced butterfly valve seat technology based on many years development while working closely with powder handling specialists. As a result the valve provides optimized performance in this harsh abrasive environment.

Product Description

The F250P/F251P Ski-Jump Valves are available in a number of executions, including wafer flanges, butt weld, RJT, clamp, and other end connections. The F250P/F251P Ski-Jump Valve is also available in a USDA compliant variation that meets the most stringent requirements for the U.S. dairy market. Pentair offers a variety of options that allow monitoring and control of the valves through a PLC control system via the Easymind control unit both standard and an IEC Ex version is available for Zone 22 installations.

Benefits

- Low wear through optimized material selection

- Unique seat stem bush technology to reduce torque and maximize seat life

- Powder tight shut-off

- Highest flow rates

- Low restriction

Top quality

- Bodies machined from solid bar stock.

- FDA compliant elastomers

- Low wear

- High cycle life (up to 3 x that of standard butterfly valves)

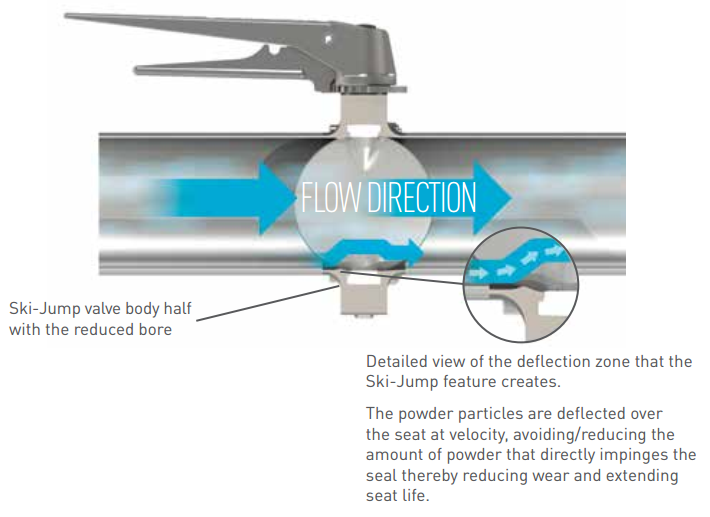

- Deflection zone (Ski-Jump) minimizes direct impingement of high velocity product particles on the sealing surfaces.

Service

- Simple, fast maintenance

- No special tools needed

Features

- Quarter turn operation.

- Optional end connections.

- One-piece disc and stem assembly.

- Fully machined 316L/304L stainless steel body.

- Bi-directional capability.

- Equal percentage characteristics.

- High Cv

- Slim profile disc.

- Integral valve position indicator.

- High grade seat materials for optimised life.

- Ski-jump feature for optimised seat life.

- Combination dual or multi position handle assembly.

- High impact reinforced polymer handle with a stainless steel drive (full stainless steel option available).

- Integral padlocking as standard on manual valves.

Automation

- Pentair F257 (Standard)

- F783E IEC Ex (Zone 22) certified control top (Optional)

- Pentair Industrial Rack and Pinion actuators (Optional)

- Manual handle (Optional)

- Travel stops (Optional)

- Positioners (Optional)

Technical Specifications

Material

Product contact area

1.4404 (AISI306L) Standard

1.4307 (AISI 304L) Min. grade

Seals

NBR / UHMWPE

Operating temperatures

For Seals

90°C (194°F) continuous

Surfaces

Product contact area Ra ≤ 0.8 μm (32 μin.)

Non product contact Ra ≤ 1.6 μm (64 μin.)

Sizes

F251 – Metric: DN 100, DN 125 DN 150

F250 – Inch OD: DN 4.0″, DN 5.0″, DN 6.0″

Connections

Wafer flanges (Pentair custom)

Clamp – ISO 2852

Thread – BS 4825

Butt weld – ISO 2037

Certifications

FDA

USDA (Special Configuration)

Function

F250/F251

Powder Valve with rack and pinion pneumatic actuator and positioner fitted