Pentair Stainless Steel Ball Valves F262

Pentair Stainless Steel Ball Valves F262DN 25 (1.0’’) – 100 (4.0’’) are used in many applications of dairy, brewery, winery, food and beverage industries. Our comprehensive valve line features both manual and pneumatic drives and a variety of options that allow monitoring and control through a PLC control system.

Product Description

Benefits

- Field replaceable seats and seals

- Adjustable gland when actuator is fitted

- Full range of accessories

- High quality precision engineered for long life and low maintenance

- Very high cycling capability

Features

- Quarter turn operation

- Full bore

- Exterior and interior surfaces are machined to hygienic standards

- Bubble tight shut-off for reliability

- A range of end connections including BSM/RJT and IDF

- Two piece construction

- Precision 316 S/S ball and stem as standard

- PTFE seats and seals as standard

Functional description

Pentair Stainless Steel Ball Valves can be operated either by a manual handle or remotely controlled by an automated pneumatic actuator. The manual version comes standard with a dual position handle notch plate. The automated version valve can be supplied in three configurations, Spring to Close (STC), Spring to Open (STO) or Double acting (DA).

Fields of application

An universal stainless steel ball valve for isolation and control of chemical and other process fluids in the food, dairy, brewing, pharmaceutical and beverage industries. Our ball valves are designed to be easily automated with the Pentair Vertical SS Actuator, combined with the Easymind Electronic Control Top. Other automation options can also be made with other Pentair rack and pinion actuators upon special request.

Technical Data

Size range: DN 25 (1.0″) – 100 (4.0″)

Pressure rating: DN 25 – 65 = 10bar. DN 80 – 100 = 6bar.

Temperature rating: -30°C to 220°C

End connections: BSM (RJT) (std). IDF (ISO 2853, BS 4825). Butt Weld (refer factory). Clamp Ends (refer factory).

Optional Valve Variants

- F262C CIP Ball Valve automated: For automated cleaning/flushing of the body cavity

- F262 Ball Valve with lockable handle: For securing valve operation

- F262C FLS Ball Valve with flushing ports: For a flushable feature on manual valves

Technical Specification

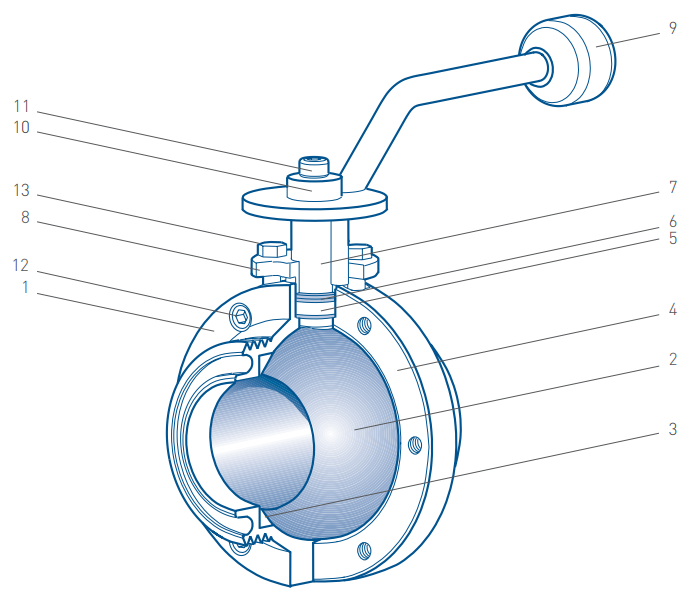

Parts List

| No. | Description | Material | Standard |

| 1 | Body | 316L S/S | ASTM A276/ASTM A743 8M |

| 2 | Ball | 316L S/S | ASTM A276 |

| 3 | Seat | PTFE Glass reinforced PTF |

– – |

| 4 | Body seal | PTFE | – |

| 5 | Stem seal | PTFE | – |

| 6 | Gland packing | PTFE | – |

| 7 | Stem | 316L S/S | ASTM A276 |

| 8 | Gland follower | 303 S/S | – |

| 9 | Handle | 304 S/S | ASTM A276 |

| 10 | Spacer | 304 S/S | – |

| 11 | Handle screw | 304 S/S | – |

| 12 | Body screw | 304 S/S | ASTM A276 |

| 13 | Gland retaining screw | 304 S/S | ASTM A276 |

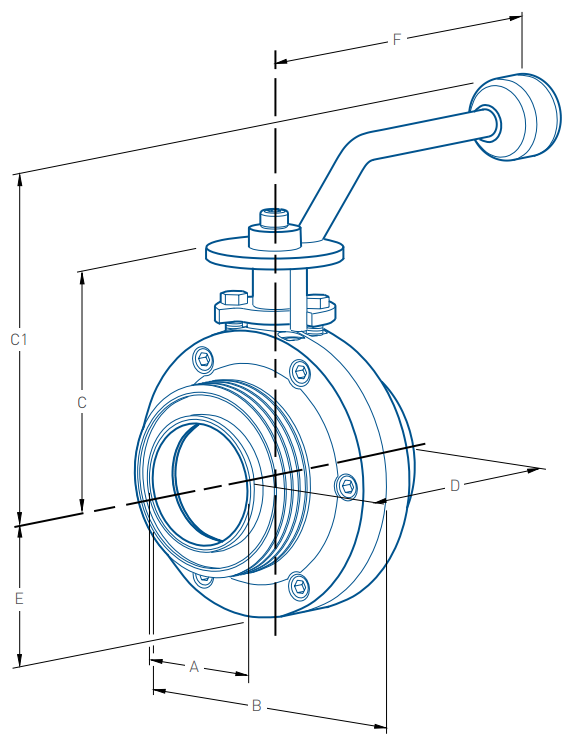

Dimensions (mm)

| Valve size | Stem connection | Mass (kg) | Kv at full open |

||||||||||||

| Metric | Inch OD | A | B | C | C1 | D (BSM) | D (CLP) | D (BW) | D1 | E | F | Inches | mm | ||

| 25 | 1″ | 22 | 75 | 60 | 108 | 70 | 76 | 70 | 112 | 38 | 145 | 7/16 x 7/16 | 11.1 x 11.1 | 1.3 | 39 |

| 40 | 1.5″ | 35 | 89 | 68 | 119 | 76 | 87 | 76 | 118 | 45 | 145 | 7/16 x 7/16 | 11.1 x 11.1 | 1.7 | 95 |

| 50 | 2″ | 47 | 106 | 77 | 127 | 85 | 100 | 85 | 129 | 53 | 145 | 7/16 x 7/16 | 11.1 x 11.1 | 2.5 | 156 |

| 65 | 2.5″ | 60 | 129 | 86 | 135 | 99 | 124 | 99 | 143 | 65 | 176 | 9/16 x 9/16 | 14.3 x 14.3 | 4.0 | 272 |

| 80 | 3″ | 73 | 152 | 96 | 147 | 118 | 136 | 136 | 162 | 76 | 176 | 9/16 x 9/16 | 14.3 x 14.3 | 6.0 | 454 |

| 100 | 4″ | 97 | 188 | 113 | 161 | 152 | 159 | 159 | 196 | 94 | 206 | 9/16 x 9/16 | 14.3 x 14.3 | 11.0 | 852 |

Notes

C = The center line to top of mounting surface when actuated.

C1 = The valve center line to top of manual valve.

D = The overall length for bare valves.

D1 = The overall length for BSM ended valves with union fitted to both ends.

Kv = The volume of water in m3/hr that will pass through a given valve opening at a pressure drop of 1bar (100kPa) at 20°C.

Cv = 1.155 Kv.

Dimensions are nominal to ±1mm.

Pressure/Temperature Rating

PTFE seated

1000kPa (10bar) at 150°C: DN 25-65

600kPa (6bar) at 210°C: DN 80-100

RTFE seated (glass reinforced PTFE)

1000kPa (10bar) at 200°C DN 25-65

600kPa (6bar) at 180°C DN 80-100

Torque Values (Nm)

| Valve Size mm | Light Service Nm | Severe Service Nm |

| 25 | 10 | 20 |

| 40 | 13 | 25 |

| 50 | 15 | 30 |

| 65 | 20 | 40 |

| 80 | 25 | 50 |

| 100 | 30 | 60 |

Selection Guide